Home » Our depacking solutions

The Bio-SV is designed to achieve optimal separation between packaging and the organic matter it contains. Our depacking system has a high processing capacity, ranging from 10 to 30 tons per hour depending on the type of waste.

The separation system is specially designed to extract high-quality organic matter, ideal for anaerobic digestion. The outputs comply strict European regulations, with plastic impurity content of less than 0.3% dry matter.

The Bio-SV was designed following two principles: ease of use and maintenance:

The plug-and- play depacker made in France

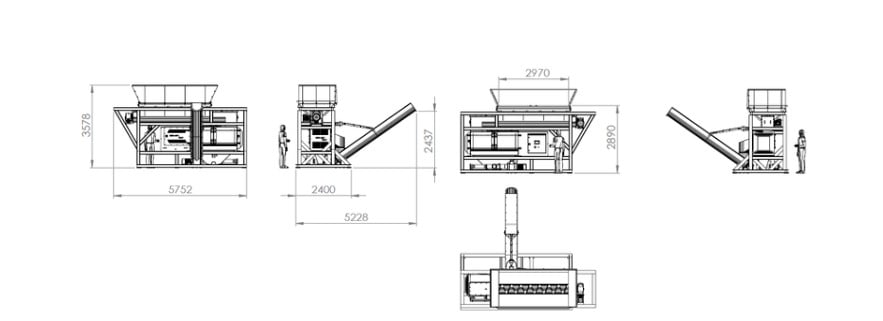

Developed to provide a depacking solution for facilities processing up to 10 000 tons of packaged biowaste per year, the Bio-SV Compact delivers a level of separation between packaging and organic material matching the performance of the Bio-SV.

The major innovation of the Bio-SV Compact is its fully integrated design: the entire depacking line is concentrated on a single frame. The Bio-SV Compact can be easily transported, installed on site, and only needs to be connected to water and electricity to start operating.

The Bio-SV Compact is built on the fundamentals that have made the Bio-SV successful: reliability, ease of use and ease of maintenance.

The proven and simple beating operating principle, combined with well-engineered design and high-quality materials ensures maximum reliability.

Following the same approach as the Bio-SV, the Bio-SV Compact was designed to facilitate maintenance. It features wide access to the various components. Consumables and parts exposed to impacts are easy and inexpensive to replace.

The Bio-SV Compact features the same interface as the Bio-SV, with an intuitive touchscreen, preloaded recipes, automatic start/stop and real-time performance monitoring.

Whether due to space constraints, limited feedstock, or tight budgets, the Bio-SV Compact makes highly constrained projects possible.